Basée sur la mondialisation intérieure, avec une vision large

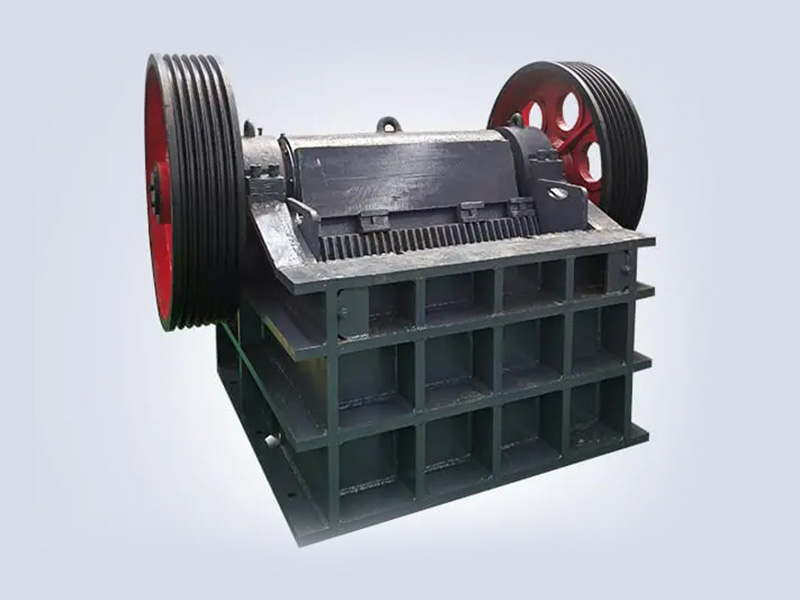

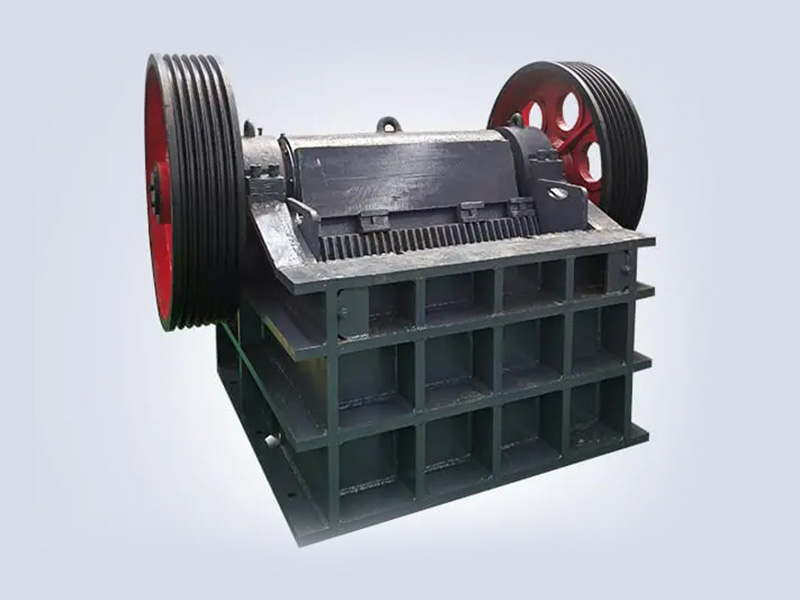

Granite, as a material with high hardness, is generally crushed using crushers with high compressive strength. Our company produces a wide variety of crushing equipment, among which for granite materials, we recommend common equipment with strong crushing force such as jaw crushers and mobile crushers. These are all suitable as granite stone crushing equipment, and users can choose the appropriate one according to their own production situation.

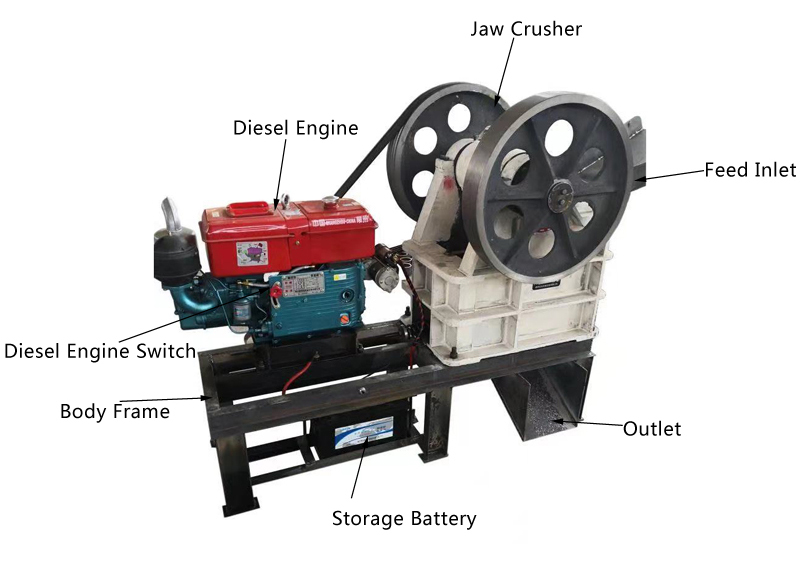

The motor drives the pulley, and the moving jaw moves up and down under the drive of the eccentric shaft. As a result, the angle between the elbow plate and the moving jaw increases and then decreases. The moving jaw and the fixed jaw sometimes approach and sometimes move away. When they approach, the material is crushed by compression, and when they move away, the qualified crushed material is discharged from the lower discharge port. With the continuous rotation of the electric motor, the moving jaw of the granite jaw crusher performs periodic crushing and discharging, achieving mass production of materials.

1. Strong breaking force. Granite crusher crushes materials with such hardness, with strong crushing force, good crushing effect, and high crushing efficiency.

2. High production capacity. The granite stone crusher adopts advanced design concepts and manufacturing processes, with high overall crushing efficiency and strong production capacity.

3. Low failure rate. The granite crusher adopts wear-resistant and wear-resistant components, coupled with the application of high-quality steel as a whole, which makes the equipment have a long service life and a low failure rate during the operation of crushing granite.

4. There are obvious investment advantages. Whether it is a jaw crusher or a mobile crushing station, for users with different needs, as long as they choose the right granite stone crusher, they can achieve high economic benefits, short capital recovery cycles, and investment advantages.

Granite crushing equipment is mainly suitable for industries such as building materials, transportation, energy, cement, mining, chemical, railway, etc. Granite crusher is capable of crushing ore rocks with a feed particle size not exceeding 500mm and a compressive strength not exceeding 350Mpa. It is not suitable for crushing ores or viscous materials with excessive surface moisture.

|

Modèle

|

Taille des particules d'alimentation (mm)

|

Taille des particules rejetées (mm)

|

Capacité (t/h)

|

Puissance du moteur (kw)

|

Poids(t)

|

Dimension (mm)

|

|

PE-150×250

|

125

|

10-40

|

2-7

|

5.5

|

0.5

|

720×660×850

|

|

PE-200×300

|

180

|

15-50

|

3-9

|

7.5

|

0.8

|

910×750×990

|

|

PE-220×350

|

180

|

18-70

|

10

|

11

|

1.1

|

1000×870×990

|

|

PE-250×400

|

210

|

20-60

|

15-20

|

15

|

2

|

1300×1090×1270

|

|

PE-400×600

|

340

|

40-100

|

40-50

|

30

|

6

|

1730×1730×1630

|

|

PE-500×750

|

425

|

50-100

|

60-80

|

55

|

9.5

|

1980×2080×1870

|

|

PE-600×900

|

500

|

65-160

|

100

|

75

|

16.5

|

2190×2206×2300

|

|

PE-750×1060

|

630

|

80-140

|

130-150

|

90

|

25

|

2660×2430×2800

|

|

PE-150×750

|

125

|

18-48

|

15

|

15

|

2.7

|

1200×1530×1060

|

|

PE-250×750

|

210

|

25-60

|

20-30

|

22

|

5

|

1380×1750×1540

|

|

PE-250×1000

|

210

|

25-60

|

40

|

30

|

6

|

1560×1950×1390

|

|

PE-250×1200

|

210

|

25-60

|

50

|

37

|

7.5

|

2140×1660×1500

|

Prenons contact dès aujourd'hui pour trouver la bonne solution !

+8613700888841

+8613700888841

+8613700888841

+8613700888841