Basée sur la mondialisation intérieure, avec une vision large

The pebble crusher has the characteristics of high crushing ratio, uniform product particle size, simple structure, reliable operation, easy maintenance, and economical operating costs. Widely used in various sectors such as mining, smelting, building materials, highways, railways, water conservancy, and chemical industries, it crushes various materials with compressive strength not exceeding 320 megapascals. Jaw crusher, impact crusher, impact crusher, and box type alloy hammer crusher are the most commonly used crushing equipment in the pebble sand industry.

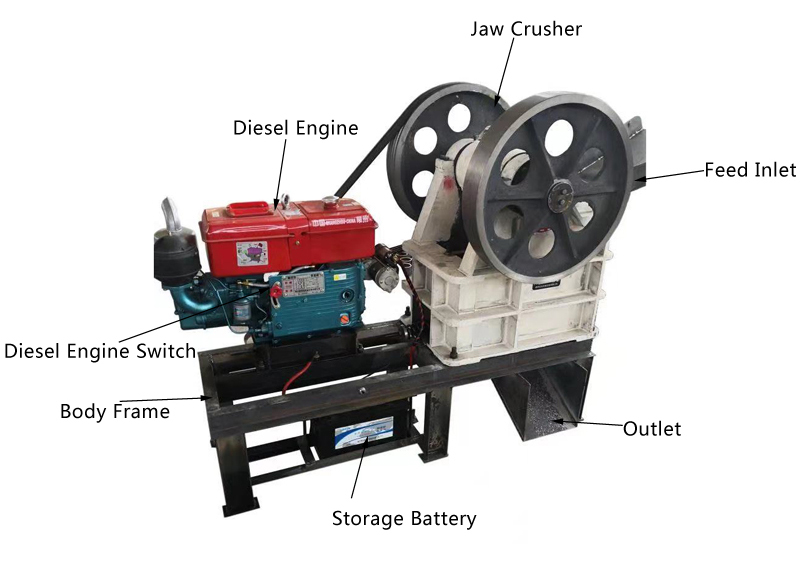

The working part of the jaw type pebble crusher consists of two jaw plates:

One is the fixed jaw plate (fixed jaw), which is vertically (or slightly inclined at the upper end) fixed on the front wall of the machine body;

And the other is the movable jaw plate (movable jaw), which is inclined in position and forms a crushing chamber (working chamber) with a larger upper part and a smaller lower part with the fixed jaw plate. The movable jaw plate performs periodic reciprocating motion against the fixed jaw plate, sometimes separating and sometimes approaching. When separated, the material enters the crushing chamber and the finished product is discharged from the lower part; When approaching, the material placed between the two jaw plates is crushed by compression, bending, and splitting. Jaw crushers can be divided into simple swing jaw crushers (simply swing jaw crushers) according to the swing mode of the movable jaw plate. There are three types of jaw crushers: complex swing jaw crushers (compound swing jaw crushers) and comprehensive swing jaw crushers.

1. Low noise and minimal dust.

2. Its crushing ratio is large, and the product particle size is uniform.

3. Simple structure, reliable operation, and low operating costs.

4. The lubrication system is safe and reliable, with easy component replacement and simple equipment maintenance.

5. The crushing chamber is deep and has no dead zone, which improves the feeding capacity and output.

6. Equipment energy saving: Single unit energy saving of 15% to 30%, system energy saving of more than twice.

7. The adjustment range of the discharge port is large, which can meet the requirements of different users.

1. Effectively solved the problem of high operation rate and no maintenance time caused by low output of the original limestone crusher.

2. It can complete the crushing of large limestone blocks, with a maximum crushing particle size of 1000 * 1200mm, effectively solving the problem of “tight supply of limestone on one side and inability to use a large amount of large limestone blocks stored on the other”.

3. The mixing uniformity of the two materials is good, and the dosage of desulfurization limestone is significantly increased. The dosage can reach 60%, effectively reducing the cost of raw materials.

4. Electricity consumption has decreased. Reducing electricity consumption by 1-2 kWh/t per ton of limestone can save 100000 yuan in electricity costs annually.

5. The small particle size of waste, only 2-15mm, effectively solves the problem of large limestone particle size, frequent blockage and even affecting the output of the grinding machine.

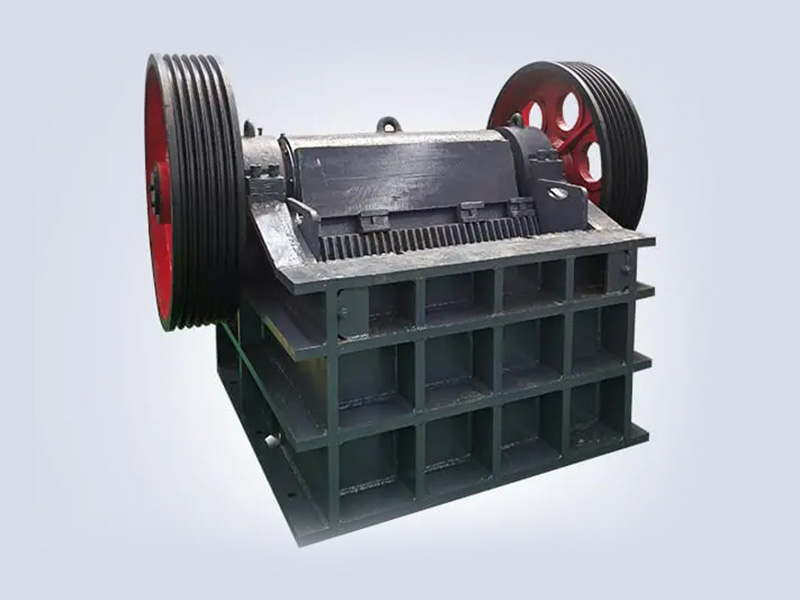

The E-type crusher is widely used in industries such as mining, smelting, building materials, highways, railways, water conservancy, and chemical engineering.

E-type crusher, also known as jaw crusher, is a commonly used crushing equipment, mainly used for medium particle size crushing of various ores and large materials.

|

Modèle

|

Feed partical size(mm)

|

discharge partical size(mm)

|

Capacity(t/h)

|

Motor power(kw)

|

Poids(t)

|

Dimension(mm)

|

|

PE-150×250

|

125

|

10-40

|

2-7

|

5.5

|

0.5

|

720×660×850

|

|

PE-200×300

|

180

|

15-50

|

3-9

|

7.5

|

0.8

|

910×750×990

|

|

PE-220×350

|

180

|

18-70

|

10

|

11

|

1.1

|

1000×870×990

|

|

PE-250×400

|

210

|

20-60

|

15-20

|

15

|

2

|

1300×1090×1270

|

|

PE-400×600

|

340

|

40-100

|

40-50

|

30

|

6

|

1730×1730×1630

|

|

PE-500×750

|

425

|

50-100

|

60-80

|

55

|

9.5

|

1980×2080×1870

|

|

PE-600×900

|

500

|

65-160

|

100

|

75

|

16.5

|

2190×2206×2300

|

|

PE-750×1060

|

630

|

80-140

|

130-150

|

90

|

25

|

2660×2430×2800

|

|

PE-150×750

|

125

|

18-48

|

15

|

15

|

2.7

|

1200×1530×1060

|

|

PE-250×750

|

210

|

25-60

|

20-30

|

22

|

5

|

1380×1750×1540

|

|

PE-250×1000

|

210

|

25-60

|

40

|

30

|

6

|

1560×1950×1390

|

|

PE-250×1200

|

210

|

25-60

|

50

|

37

|

7.5

|

2140×1660×1500

|

Prenons contact dès aujourd'hui pour trouver la bonne solution !

+8613700888841

+8613700888841

+8613700888841

+8613700888841