Based on domestic globalization, with a broad vision

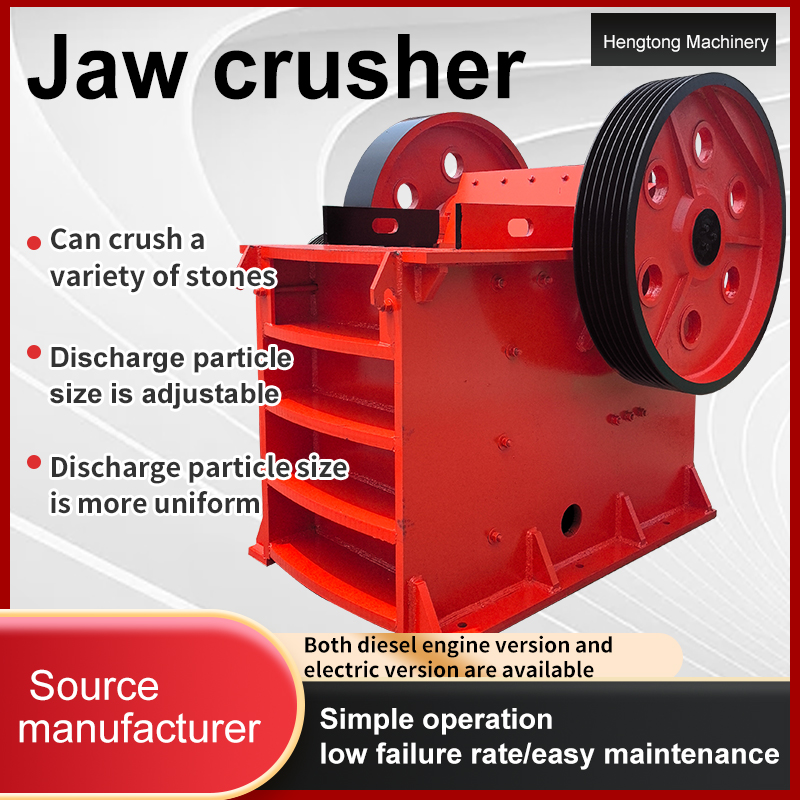

Jaw Crusher is the typical crusher among crusher, which can crush a variety of stone. It falls into two types: that produces coarse gravel and that produces sand. The former is used mainly to break big stones into smaller one, and the latter fine gravel.

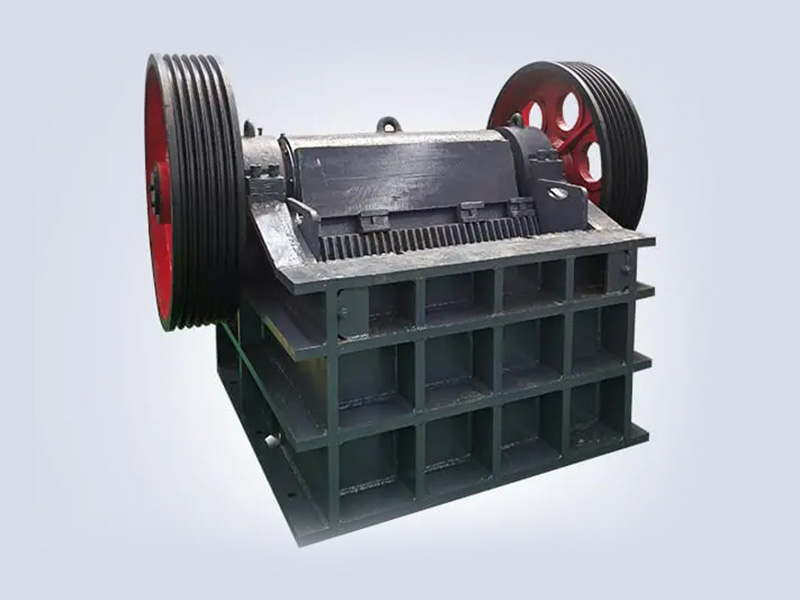

Jaw Crusher, also known is a crusher composed of two jaw plates, a moving jaw and a stationary jaw, which simulates the movement of two jaws of an animal to complete the crushing operation of the material. Simple structure, easy manufacture and reliable work.

The E-type crusher, commonly known as the E-type crusher, E-type crusher, or jaw crusher, is also known as the tiger mouth. It consists of two jaw plates, the moving jaw and the stationary jaw, which form the crushing chamber. It simulates the movement of the two jaws of animals to complete material crushing operations.

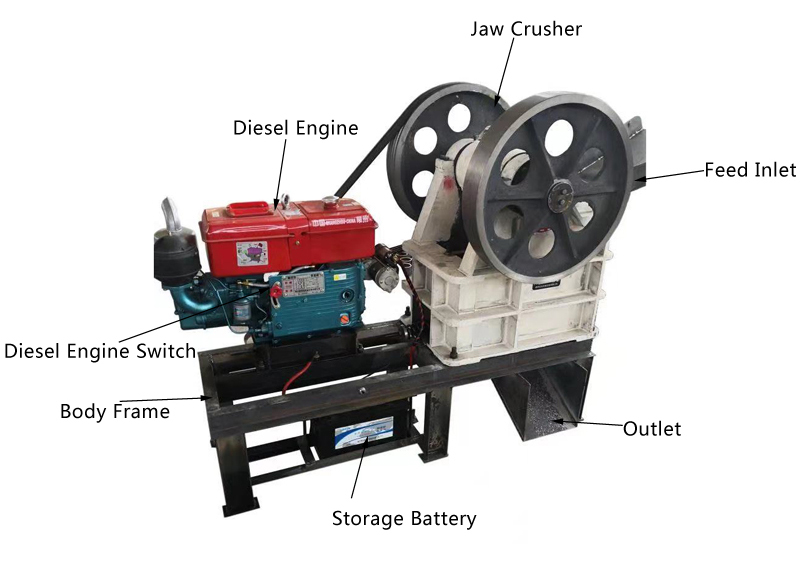

The motor drives the belt and pulley, and the movable jaw moves up and down through an eccentric shaft. When the movable jaw rises, the angle between the elbow plate and the movable jaw increases, thereby pushing the movable jaw plate closer to the fixed jaw plate. At the same time, the material is crushed or split, achieving the purpose of crushing; When the movable jaw descends, the angle between the elbow plate and the movable jaw decreases. Under the action of the tension rod and spring, the movable jaw plate separates from the fixed jaw plate, and the crushed material is discharged from the lower outlet of the crushing chamber. As the electric motor continues to rotate, the crusher’s jaw undergoes periodic motion to crush and discharge materials, achieving mass production.

1. Low noise and minimal dust.

2. Its crushing ratio is large, and the product particle size is uniform.

3. Simple structure, reliable operation, and low operating costs.

4. The lubrication system is reliable, the components are easy to replace, and the equipment maintenance is simple.

5. The crushing chamber is deep and has no dead zone, which improves the feeding capacity and output.

6. Equipment energy saving: Single unit energy saving of 15% to 30%, system energy saving of more than twice.

7. The adjustment range of the discharge port is large, which can meet the requirements of different users.

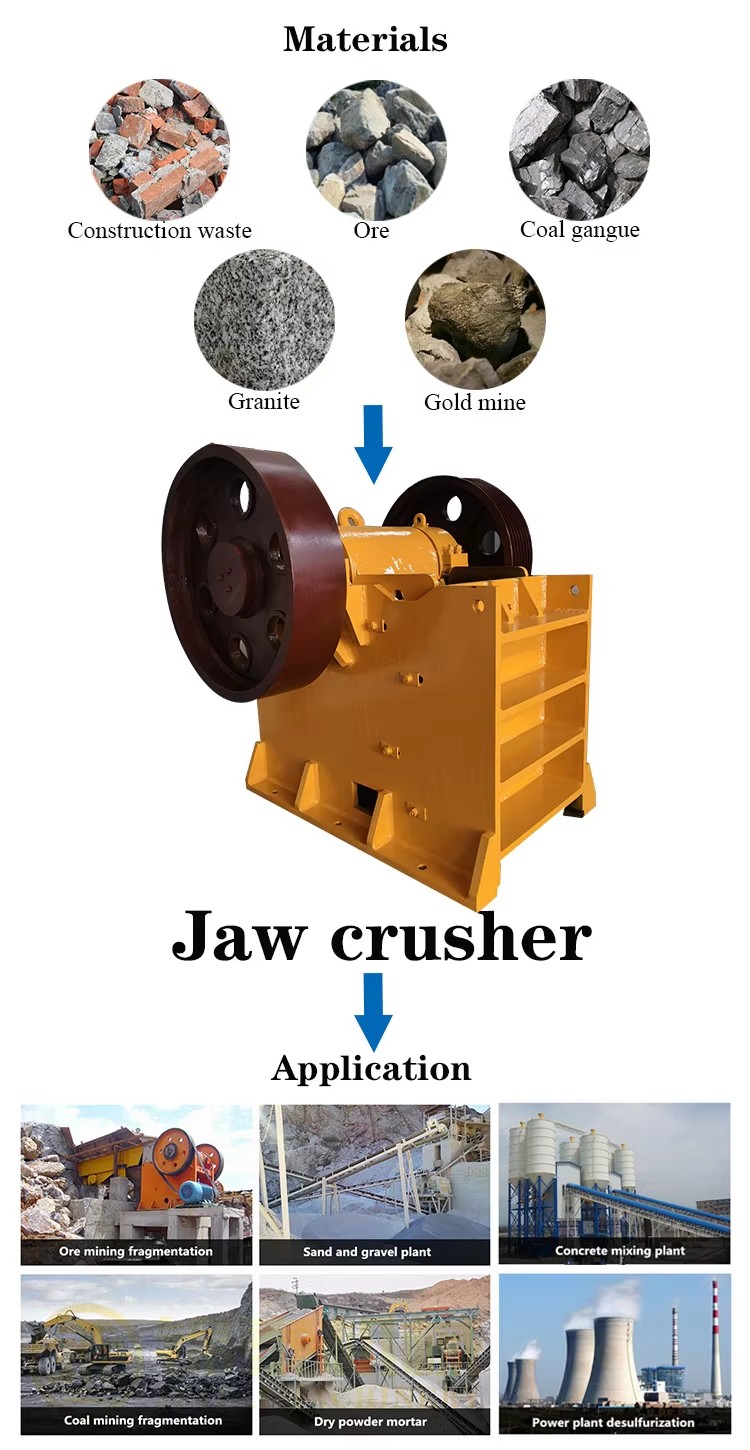

1. This series of crushers is suitable for crushing various soft and hard ores with compressive strength not exceeding 320MPa (megapascal) and side length not exceeding 500mm, such as quartz, copper ore, river pebbles, granite, basalt, etc.

2. The stone products crushed by the E-type crusher are widely used in many sectors such as mining, smelting, building materials, highways, railways, cement, construction, water conservancy, and chemical industry.

|

Model

|

Feed partical size(mm)

|

discharge partical size(mm)

|

Capacity(t/h)

|

Motor power(kw)

|

Weight(t)

|

Dimension(mm)

|

|

PE-150×250

|

125

|

10-40

|

2-7

|

5.5

|

0.5

|

720×660×850

|

|

PE-200×300

|

180

|

15-50

|

3-9

|

7.5

|

0.8

|

910×750×990

|

|

PE-220×350

|

180

|

18-70

|

10

|

11

|

1.1

|

1000×870×990

|

|

PE-250×400

|

210

|

20-60

|

15-20

|

15

|

2

|

1300×1090×1270

|

|

PE-400×600

|

340

|

40-100

|

40-50

|

30

|

6

|

1730×1730×1630

|

|

PE-500×750

|

425

|

50-100

|

60-80

|

55

|

9.5

|

1980×2080×1870

|

|

PE-600×900

|

500

|

65-160

|

100

|

75

|

16.5

|

2190×2206×2300

|

|

PE-750×1060

|

630

|

80-140

|

130-150

|

90

|

25

|

2660×2430×2800

|

|

PE-150×750

|

125

|

18-48

|

15

|

15

|

2.7

|

1200×1530×1060

|

|

PE-250×750

|

210

|

25-60

|

20-30

|

22

|

5

|

1380×1750×1540

|

|

PE-250×1000

|

210

|

25-60

|

40

|

30

|

6

|

1560×1950×1390

|

|

PE-250×1200

|

210

|

25-60

|

50

|

37

|

7.5

|

2140×1660×1500

|

Let's Connect Today To Find The Right Solution!

+8613700888841

+8613700888841

+8613700888841

+8613700888841