Based on domestic globalization, with a broad vision

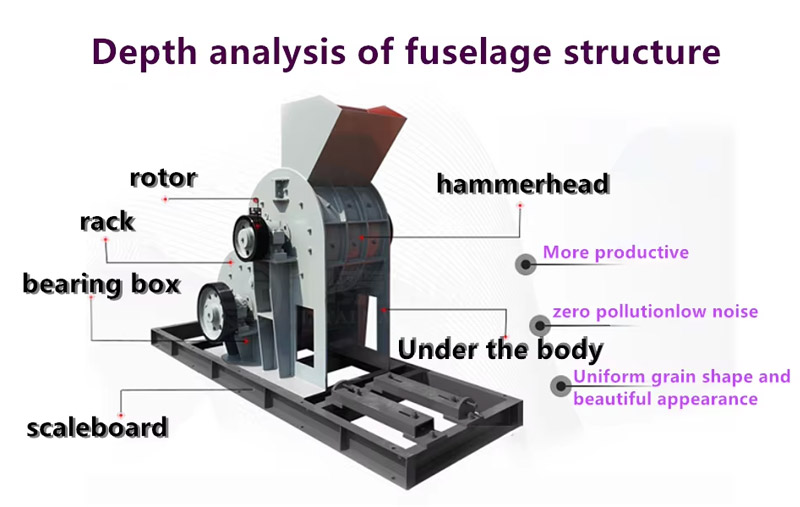

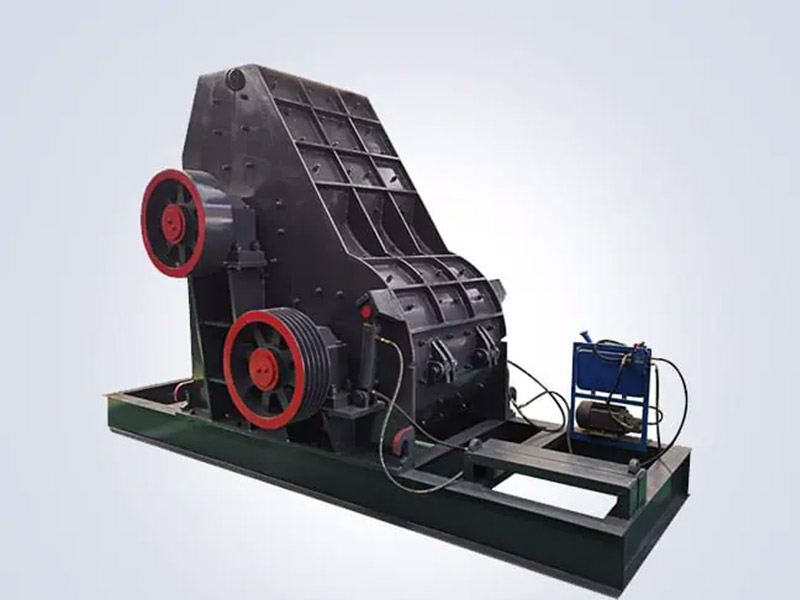

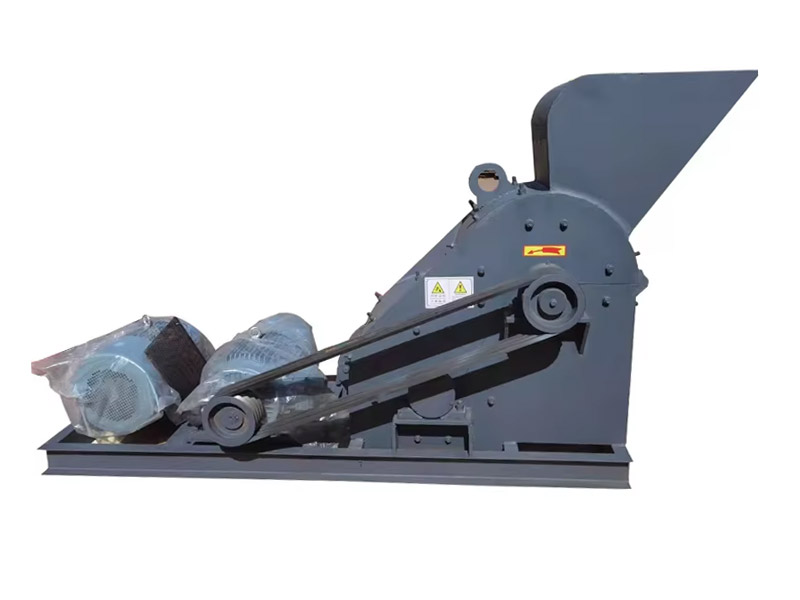

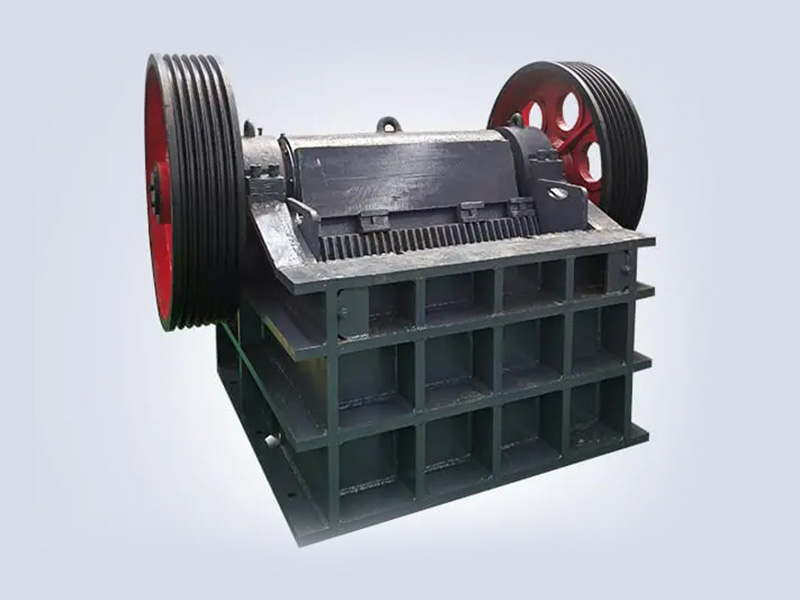

Double Stage Hammer Crusher has no grate bottom, no strict requirements on material moisture content, there is no paste blocking sieve plate problem, there is no fine powder can not be discharged in time, repeated crushing problem, so high crushing efficiency, there is no invalid hammer wear phenomenon. Only need one person can easily open and close, not only light and fast and safe and reliable, easy maintenance.

When the two-stage crusher is working, under the drive of the dual motors, the two sets of rotors connected in series rotate at high speed simultaneously. The material is immediately crushed by the hammer head of the rapidly rotating lower rotor in the machine cavity after being crushed by the upper rotor. The materials in the cavity collide and crush each other at high speed, achieving the effect of hammer powder and material powder, forming coal slag particles with a discharge particle size of less than 3 millimeters. This particle size can fully meet the requirements of brick and tile manufacturers as internal combustion bricks.

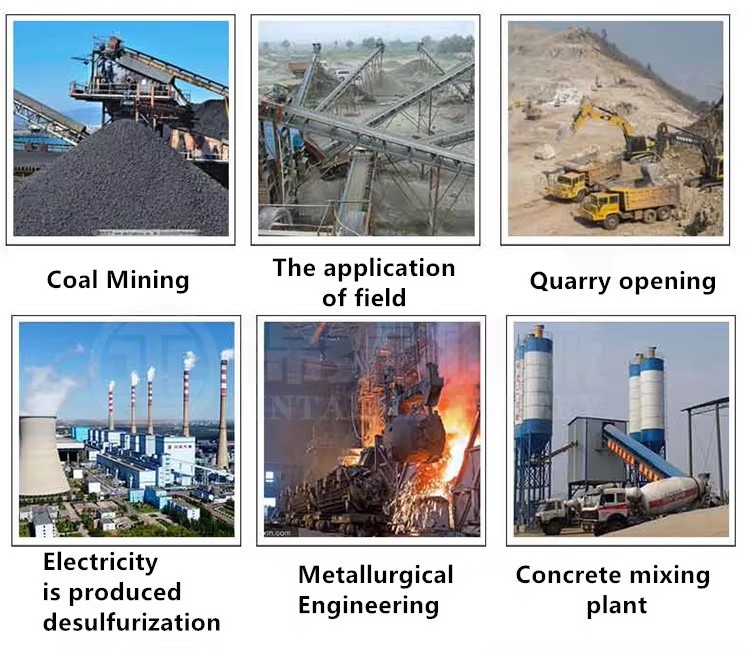

The two-stage crusher has the advantages of reliable operation, convenient maintenance, and long service life. It is mainly suitable for crushing materials such as coal slag, slag, slag, shale, coal gangue, construction waste, and building waste in calcite, limestone, and brick and tile factories. It solves the problem of using gangue and coal slag as additives and internal fuels in brick factories; The challenge of crushing high moisture materials for producing standard bricks and hollow bricks using gangue and shale.

1, the upper and lower rotors work simultaneously, the upper and lower rotors rotate at the same time, the crushing rate is high, equivalent to two hammer crushers.

2, hydraulic unpacking device, convenient maintenance.

3, the discharge particle size is uniform and adjustable, and the size of the discharge particle size can be controlled.

4, there is no screen bottom, there is no high requirement for the humidity of the material, it does not block the raw materials, and the effect of crushing wet materials is obvious.

5, it can crush multiple raw materials at the same time, and one device can crush various stones!

|

Type specification

|

Weight(T)

|

Output(t/h)

|

The number of hammerhead(PCS)

|

The hammerhead weight(KG/PC)

|

Motor type(KW)

|

Disharging granularity(mm)

|

|

2PC-600*400

|

1

|

10-15

|

24

|

3.5

|

18.5+18.5

|

2-3

|

|

2PC-600*600

|

1.3

|

15-20

|

40

|

3.5

|

22+22

|

2-3

|

|

2PC-600*800

|

1.8

|

20-30

|

48

|

3.5

|

30+22

|

2-3

|

|

2PC-800*600

|

3

|

30-40

|

40

|

7

|

45+37

|

2-3

|

|

2PC-800*800

|

3.5

|

40-50

|

48

|

7

|

55+45

|

2-3

|

|

2PC-1000*800

|

5.5

|

50-60

|

48

|

8

|

55+75

|

2-3

|

|

2PC-1000*1000

|

7

|

60-90

|

52

|

8

|

90+75

|

2-3

|

|

2PC-1000*1200

|

8

|

70-90

|

56

|

8

|

110+90

|

2-3

|

|

2PC-1000*1400

|

8.5

|

100-120

|

60

|

10

|

110+132

|

2-3

|

|

2PC-1200*1400

|

9

|

120-130

|

60

|

12

|

132+160

|

2-3

|

|

2PC-1400*1600

|

13

|

130-180

|

72

|

20

|

160+200

|

2-3

|

Let's Connect Today To Find The Right Solution!

+8613700888841

+8613700888841

+8613700888841

+8613700888841