Based on domestic globalization, with a broad vision

Mobile two-stage sand making machine has no grate bottom, no strict requirements on material moisture content, there is no paste blocking sieve plate problem, there is no fine powder can not be discharged in time, repeated crushing problem, so high crushing efficiency, there is no invalid hammer wear phenomenon. Only need one person can easily open and close, not only light and fast and safe and reliable, easy maintenance.

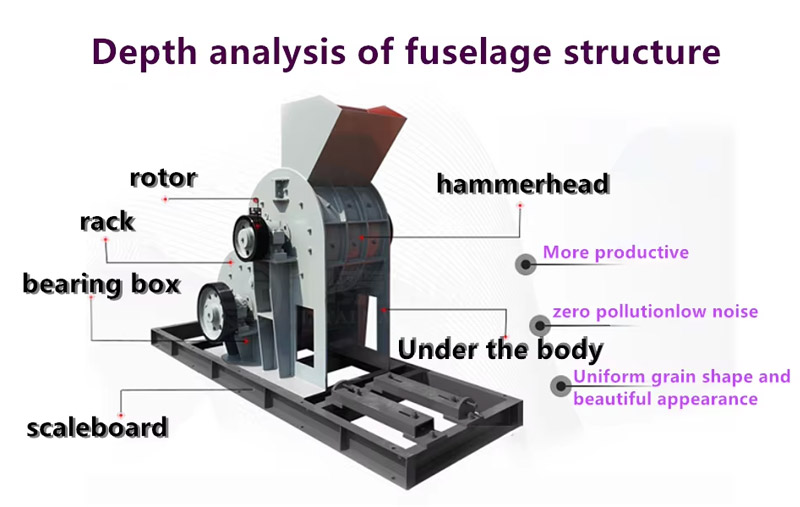

When the two-stage crusher is working, under the drive of the dual motors, the two sets of rotors connected in series rotate at high speed simultaneously. The material is immediately crushed by the hammer head of the rapidly rotating lower rotor in the machine cavity after being crushed by the upper rotor. The materials in the cavity collide and crush each other at high speed, achieving the effect of hammer powder and material powder, forming coal slag particles with a discharge particle size of less than 3 millimeters. This particle size can fully meet the requirements of brick and tile manufacturers as internal combustion bricks.

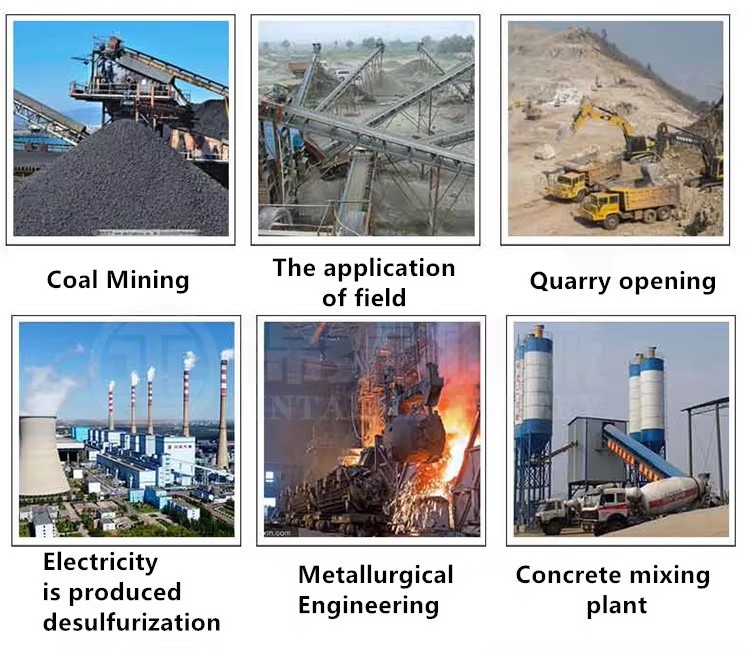

The two-stage crusher has the advantages of reliable operation, convenient maintenance, and long service life. It is mainly suitable for crushing materials such as coal slag, slag, slag, shale, coal gangue, construction waste, and building waste in calcite, limestone, and brick and tile factories. It solves the problem of using gangue and coal slag as additives and internal fuels in brick factories; The challenge of crushing high moisture materials for producing standard bricks and hollow bricks using gangue and shale.

1. Special displacement gap adjustment technology, the hammerhead does not need to be repaired after wear and tear, and can be repeatedly used to move the position. One hammerhead can support three hammerheads for use.

2. The discharge particle size is uniform, the crushing ratio is large, the output is high, and the energy consumption is low. It can crush more than 20 tons of material per hour, and the cost of crushing one ton of coal slag does not exceed 1.8 yuan.

3. The two-stage crusher is suitable for the fine crushing of brittle materials, without clogging, with less dust and low noise.

4. The sieve free two-stage crusher reduces the time for materials to remain in the crushing chamber and improves the service life of vulnerable parts.

5. Quick maintenance, the side doors on the upper side of the crusher can be easily opened, making the crusher easy to maintain and vulnerable.

6. We use a high alloy wear-resistant hammer head and a combination of hammer head and handle, only replacing the hammer head and not the handle.

7. Bidirectional rotation, through continuous equal shift bidirectional operation, can evenly wear between the hammer head and the crushing gear plate, reducing the frequency of downtime for replacing vulnerable parts.

|

Type specification

|

Weight(T)

|

Output(t/h)

|

The number of hammerhead(PCS)

|

The hammerhead weight(KG/PC)

|

Motor type(KW)

|

Disharging granularity(mm)

|

|

2PC-600*400

|

1

|

10-15

|

24

|

3.5

|

18.5+18.5

|

2-3

|

|

2PC-600*600

|

1.3

|

15-20

|

40

|

3.5

|

22+22

|

2-3

|

|

2PC-600*800

|

1.8

|

20-30

|

48

|

3.5

|

30+22

|

2-3

|

|

2PC-800*600

|

3

|

30-40

|

40

|

7

|

45+37

|

2-3

|

|

2PC-800*800

|

3.5

|

40-50

|

48

|

7

|

55+45

|

2-3

|

|

2PC-1000*800

|

5.5

|

50-60

|

48

|

8

|

55+75

|

2-3

|

|

2PC-1000*1000

|

7

|

60-90

|

52

|

8

|

90+75

|

2-3

|

|

2PC-1000*1200

|

8

|

70-90

|

56

|

8

|

110+90

|

2-3

|

|

2PC-1000*1400

|

8.5

|

100-120

|

60

|

10

|

110+132

|

2-3

|

|

2PC-1200*1400

|

9

|

120-130

|

60

|

12

|

132+160

|

2-3

|

|

2PC-1400*1600

|

13

|

130-180

|

72

|

20

|

160+200

|

2-3

|

Let's Connect Today To Find The Right Solution!

+8613700888841

+8613700888841

+8613700888841

+8613700888841