На основе внутренней глобализации, с широким видением

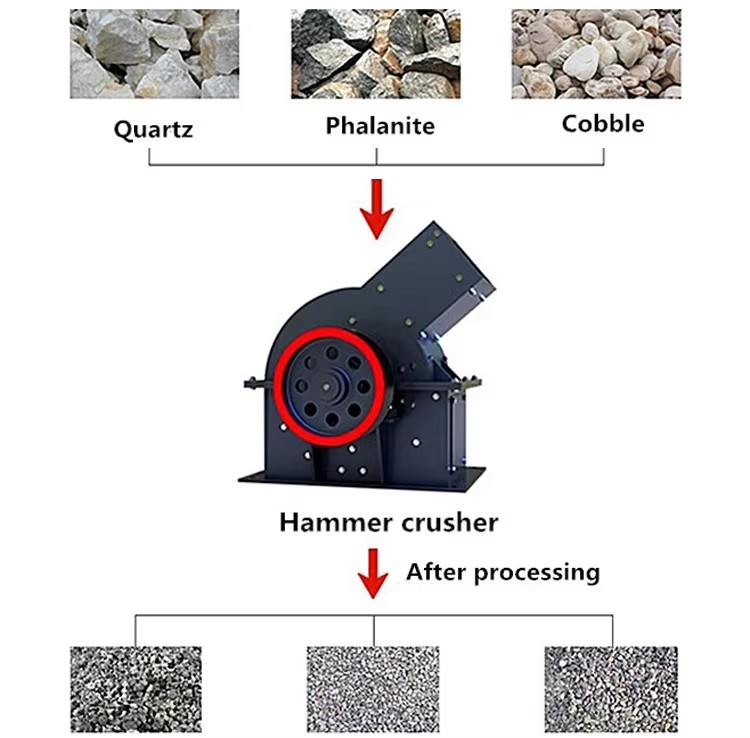

The main working part of hammer crusher is rotors with hammer. The rotors consist of main shaft, disk, pin shaft and hammers. The motor drives the rotors to rotate quickly in the crushing cavity. Raw materials enter the crusher through the feed opening and are stricken, impacted, cut and ground by the high-speed hammer to small size.

1.The output particle size below 3 mm and below 2 mm accounts for more than 90%. Uniform particle adjustable, especially suitable

for the production of porous brick, thin-walled brick.

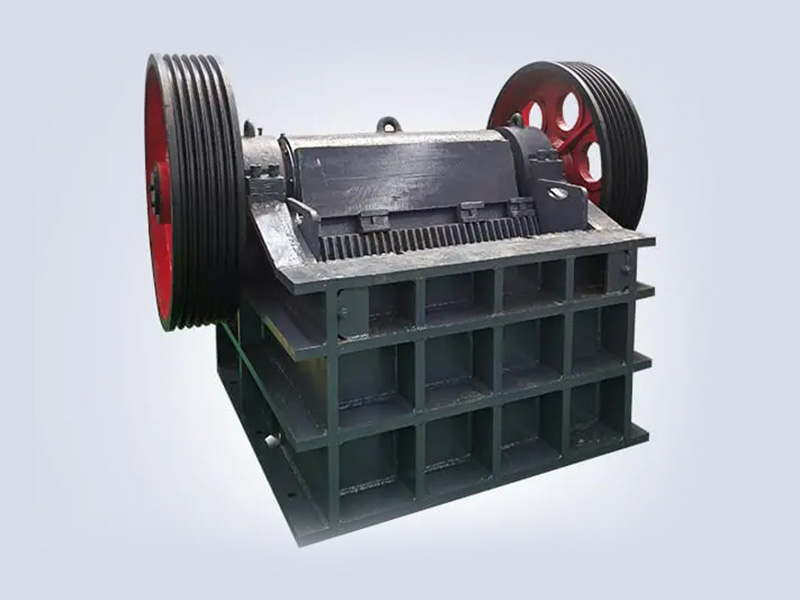

2.Double – rotor two – stage grinding, not grate mesh, wet material does not plug.

3.Hammer head, liner bidirectional clearance, at any time to control the size of the discharge.

4.Double shaft and double flying wheel, stable operation, high inertia, power saving more than 20%.

5.With its own hydraulic lifting device, the replacement of hammerhead maintenance saves time and effort.

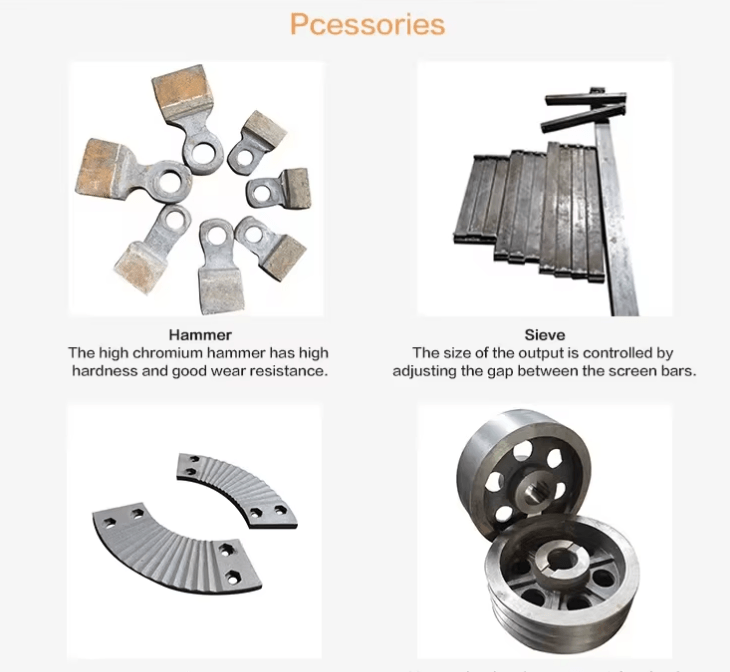

⑴ Working hammer head, cast with new technology, has wear resistance and impact resistance.

⑵ The required granularity can be adjusted according to customer requirements.

(3)The hammer broke the structural seal of the machine body, solving the problems of dust pollution and body leakage in the crushing workshop.

(4)The overall design has the advantages of beautiful appearance, compact structure, few vulnerable parts, and easy maintenance, making it an upgraded product.

⑸ Compact structure, beautiful appearance, good wear resistance, and easy maintenance.

The stone crusher is used to crush materials such as coal, salt, gypsum, bricks, limestone, etc. It is also used for crushing fiber structures, strong elasticity and toughness of broken wood, paper, or crushed asbestos cement. Hammer crushers can not only be used for crushing production lines, sand production lines, but also for crushing stone materials in mineral processing production lines.

|

Модель

|

Количество молотков

|

Вес молотка (кг)

|

Мощность (кВт)

|

Вес(т)

|

Производительность (т/ч)

|

|

ПЭ-200*300

|

9

|

1.7

|

5.5

|

0.15

|

1-3

|

|

PE-240*450

|

16

|

2.5

|

7.5

|

0.35

|

3-5

|

|

PE-310*520

|

20

|

3

|

15

|

0.55

|

7-8

|

|

PE-400*600

|

20

|

5

|

22

|

0.9

|

10-15

|

|

PE-600*600

|

24

|

5

|

30

|

1.3

|

15-20

|

|

PE-600*800

|

24

|

8

|

55

|

2

|

20-30

|

|

PE-800*800

|

28

|

8

|

75

|

2.5

|

25-35

|

|

PE-800*1000

|

28

|

15

|

90

|

3.5

|

30-40

|

|

PE-1000*1000

|

32

|

15

|

110

|

4

|

40-50

|

Давайте соединимся сегодня, чтобы найти правильное решение!

+8613700888841

+8613700888841

+8613700888841

+8613700888841